When the starter quit in DaMom's car last week I discovered just how poorly the designers regard any technician or shade tree mechanic. It's not that I didn't know this before but It's job that should take 15 minutes to do, including collecting and storing the necessary tools.

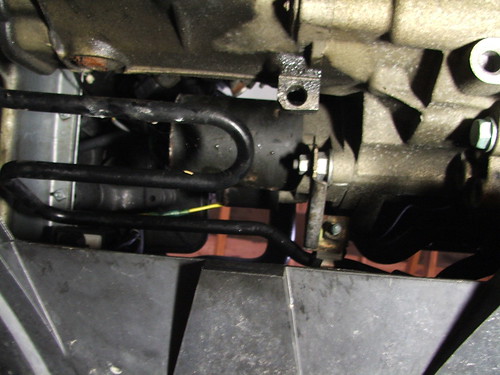

Any manual I could find inferred the starter was to be removed from under the car. Here is the underside view:

That black cylinder behind the S-bending pipe is the starter. Just move the pipe out of the way right? Wrong! It's an air conditioning line that only flexes so far. Why it has to make those bends right here is beyond me as the pipes seem to double back toward the other side of the car.

That black cylinder behind the S-bending pipe is the starter. Just move the pipe out of the way right? Wrong! It's an air conditioning line that only flexes so far. Why it has to make those bends right here is beyond me as the pipes seem to double back toward the other side of the car.So how can the starter come out?

Through the top of course:

What? Can't you see it in there? It's under all that wiring with no service loop, the cable protector, and the battery box.

What? Can't you see it in there? It's under all that wiring with no service loop, the cable protector, and the battery box.So here's what had to be removed to get this gem out:

- The battery cover

- The positive voltage distribution board (it sits on top of the battery)

- The battery

- The battery tray

- The little nut that shall not be seen which holds the stupid plastic cable protector in place

- Push the much to tight wiring out of the way

- and finally remove the starter bolts

It makes my truck look really nice and simple to work on....not to mention my bikes.

g

No comments:

Post a Comment